If you have other settings you d like to suggest please send an email to design help ncsu edu with the details.

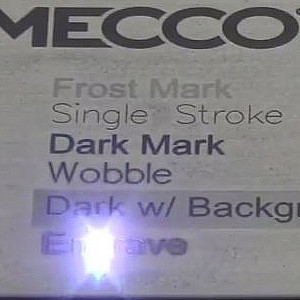

Laser it engravable aluminum settings.

Being able to engrave metal was one of the main reasons why i got a laser cutter.

It offers a wider variety of color combinations than other engravable metals.

I live near a diy workshop called techshop they have 1m worth of equipment that i can get access to for about 100 a month.

60 watt dpi 400 speed 75 power 40.

All settings noted use the default resolution which is 500 or 600 depending on the make of your laser system.

The following are suggested laser cutter configuration settings for various materials.

Aluminum is not anodized.

The recommended settings above may need adjustments for best results.

Not intended for sublimation.

One piece of equipment they have i.

This instructable will show you how to use a laser cutter to etch anodized aluminum.

Metals that are thick will require more heat energy and a slower speed setting.

When using cermark metal marking solution remember that not all metals use the same speed setting.

It is a great option for many applications.

The clear masking will protect it until you re ready to use it.

Laser it is a very versatile aluminum designed specifically to be laser engraved.

Please share your results and experiences in the comments i would love to learn more about engrav.

In this instructable i am going to show you some of my experiences.

Also available is a laser cutter user guide.